Panasonic has commercialized a connector with a unique structure that allows direct connection between an automotive FPC (flexible printed circuit) [1] and the board. This connector eliminates the need for wire harnesses [2] previously needed for connection, allowing the use of fewer components and fewer assembly person-hours for vehicles, as well as making room for improved design of automotive LED lights, etc.

Osaka, Japan – Panasonic Corporation announced today that it will launch full-scale mass production of a “Board to FPC Connector” (Series name: CF1) in July 2019, which allows the use of fewer components and fewer assembly person-hours for vehicles, as well as making room for improved design of automotive LED lights, etc.

Due to the increasing use of DRLs (daylight running lamps) [3] following changes in the law governing automotive LED lights in Europe and Japan in recent years and improved designs for vehicle compartment instrument panels, etc., demand for automotive FPCs is expected to grow, accompanied by greater use in cable connection applications such as BMSs [4]. Panasonic has designed and commercialized a connector with a unique structure that allows direct connection between the automotive FPC and the board. This connector eliminates the need for wire harnesses previously needed for connection, allowing the use of fewer components and fewer assembly person-hours, as well as enabling vehicle weight reduction and therefore lower fuel consumption.

Panasonic’s new Board to FPC Connector has the following features:

- Panasonic’s unique metal terminal connection structure, which allows direct connection between the FPC and the board, eliminates the need for relay harnesses, allowing the use of fewer components and assembly person-hours.

- The connector’s double-clip contact structure achieves excellent resistance to vibration, making it compatible with automotive applications such as LED lights and BMSs.

- The connector’s inertial lock structure prevents incomplete engagement, achieving high reliability.

Product Features

-

- Panasonic’s unique metal terminal connection structure, which allows direct connection between the FPC and the board, eliminates the need for relay harnesses, allowing the use of fewer components and assembly person-hours.

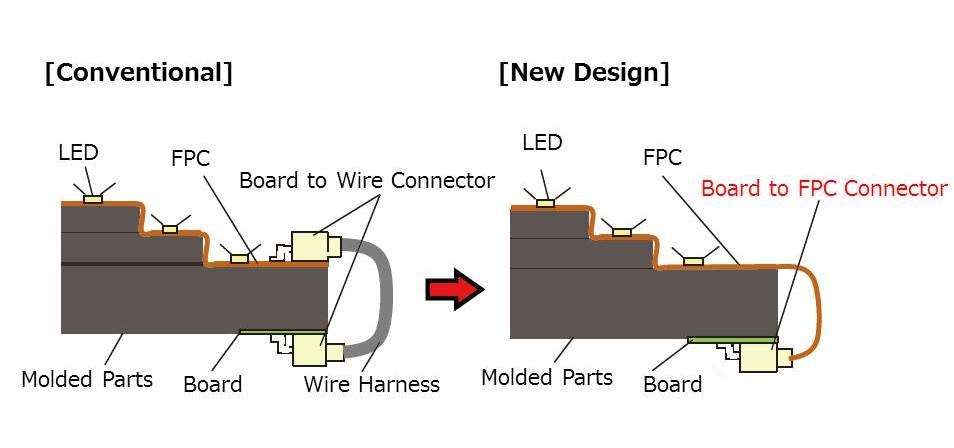

Opportunities for the use of FPCs have been expanding with the increasing refinement of the design of DRLs, rear lamps, vehicle compartment instrument panels, shift levers, etc. Although FPCs and boards are conventionally connected mainly by using relay harnesses or by soldering FPCs and boards, there are drawbacks such as the additional weight and poor assembly workability of wire harnesses. By adopting a unique structure that allows direct connection between the FPC and the board, this connector eliminates the need for relay harnesses, allowing the use of fewer components and assembly person-hours. (Fig. 1)

- Panasonic’s unique metal terminal connection structure, which allows direct connection between the FPC and the board, eliminates the need for relay harnesses, allowing the use of fewer components and assembly person-hours.

[Fig. 1] Comparison of connection methods

-

- The connector’s double-clip contact structure achieves excellent resistance to vibration, making it compatible with automotive applications such as LED lights and BMSs.

Automotive connectors are required to meet strict vibration criteria. This connector has achieved excellent resistance to vibration by adopting a unique double-clip contact structure that reliably grips the plug, i.e., the metal terminal (FPC side), and the receptacle (board side). The connector can also be used for FPCs for connecting BMS battery packs and boards, as well as for LED lights that require resistance to vibration. (Fig. 2)

- The connector’s double-clip contact structure achieves excellent resistance to vibration, making it compatible with automotive applications such as LED lights and BMSs.

[Fig. 2] Connector structure

- The connector’s inertial lock structure prevents incomplete engagement, achieving high reliability.

The connector, which is a two-piece type consisting of a plug (FPC side) and a receptacle (board side), is designed for easy connection. Furthermore, the connector has achieved high reliability by adopting an inertial lock structure capable of preventing incomplete engagement between the receptacle and plug during assembly.

Suitable Applications:

Cable connection for DRLs (headlamps), rear lamps, side mirrors, instrument panels, shift levers, steering switches, BMSs, cameras, etc.

Area of Sales:

Global

Basic Specifications:

- Rated current: Max. 2.0 A/pin

- Rated voltage: 50 V DC

- Ambient temperature: -40 to +125°C

- Contact resistance: Max. 20 mΩ (Initial)

- Insulation resistance: Min. 100 MΩ

- Dielectric strength: 1000 V AC for 1 min.

- Housing retention force: Min. 30 N (Initial)

[Term Descriptions]

[1] FPC (Flexible Printed Circuit)

Flexible circuit board

[2] Wire harness

Set (bundle) of electric wires for power supply and signal communication, used for in-vehicle wiring, etc.

[3] DRL (Daylight Running Lamps, Daytime Running Lights)

Lighting device that is also lit during the daytime

[4] BMS (Battery Management System)

Voltage monitoring system for lithium-ion batteries