Cloud native EDA tools & pre-optimized hardware platforms

While traditional mask-based lithography continues its exponentially more expensive evolution, the emergence of maskless e-beam lithography is providing a complementary path toward helping chipmakers get to market faster. Using electron beams to produce patterns on silicon wafers, e-beam lithography enables faster yield ramp since there is no need to wait for a mask to be manufactured. Additionally, more efficient cycles of learning are realized given the ability to pattern design iterations across a single wafer.

A key innovator in this space is Multibeam Corporation, based in Santa Clara, California. Founded by Silicon Valley Engineering Hall of Famer Dr. David K. Lam, Multibeam has developed the first high-resolution and high-productivity e-beam with direct write capability for fab production. Multibeam’s Multicolumn Electron Beam Lithography (MEBL) Systems are integrated with Synopsys CATS data preparation software, creating an easier and faster path from chip design to production.

“Multibeam and Synopsys have similar visions of where the industry is going, and together we can accelerate the cycles of innovation,” said Dr. Lam, Chairman & CEO of Multibeam. “Our Lithography Systems featuring Synopsys software will support chip designers and manufacturers in their quest to produce higher performance chips at a faster pace to meet the demands of today’s compute-intensive applications.”

Where Maskless E-Beam Lithography Makes Sense

Traditional lithography remains a standard in the industry, providing precision and a relatively cost-effective way to create patterns on the wafer when producing very high volumes of chips. However, cycle times can be long depending on the complexity of the masks that must be made. Maskless e-beam lithography, on the other hand, starts the direct-write process on wafers as soon as a technician feeds a file to the machine.

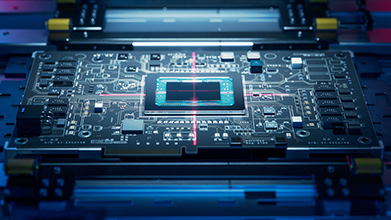

Purpose-built silicon and advanced packaging are huge enablers of high-growth applications like artificial intelligence (AI) and wireless communications. Contrary to other lithography technologies available to manufacturers today, high-productivity e-beam lithography significantly accelerates time to market. Rapid production of various design iterations is another key capability that Multibeam’s high-productivity e-beam systems enable.

Enabling Advanced Integration of Chips

Based on multiple miniature e-beam columns, Multibeam’s maskless e-beam system opens up possibilities that haven’t been available in semiconductor manufacturing. By enabling rapid cycles of learning, the system allows:

- Chip designers to conduct wafer-scale experiments where they can customize every chip on the wafer to explore new ideas

- Design changes to be implemented immediately, without having to wait for new masks

- Rapid iterations between design feedback and validation

- Fast ramp to production once the design has been validated

The MEBL system also helps accelerate system-level optimization through advanced integration of chips. By enabling chip designers to utilize next-generation interposers, they will be able to pack more chips into each package, while achieving higher chip-to-chip bandwidth and lower energy per bit transfer – all crucial for producing AI chips.

Synopsys CATS software is a key component that enables advanced integration. Multibeam’s integration of CATS software highlights its versatility for maskless, as well as mask-based, chip production flows, allowing for seamless integration. The scalable CATS software suite transcribes complex chip design data into machine-readable instructions for e-beam, laser, and multi-beam mask writer machines. The software suite provides data prep modules for data fracture, data verification, mask rule checking, mask error correction, job deck processing, layer operations, and data sizing. It also integrates into Synopsys Proteus™ full-chip mask synthesis smart manufacturing solutions for correction, which enhances resolution for better yield and supports large-volume, high-throughput data transfer.

“One of Synopsys’ goals is to make it much easier and quicker for chip designers to bring their products to market with fewer mistakes and fewer cycles, and that’s one of the key benefits of our technology as well,” said Dr. Ken MacWilliams, President of Multibeam. “In addition, Synopsys brought e-beam expertise that complemented ours, as well as a mindset geared toward building a system that would work well in a production environment.”

First System Ships This Spring

Multibeam is shipping its first MEBL system with Synopsys inside this spring. As the company continues to develop and enhance its technologies, the team looks forward to building on its collaboration with Synopsys. With faster cycle times and yield ramp, along with the ability to fix problems earlier on, chipmakers using our Multibeam system can rapidly explore new design variations that could help them differentiate their products,” said MacWilliams. “Together with Synopsys, we are enabling chip designers and chip manufacturers to bring new ideas to life, faster and more efficiently.”

“We are excited about our collaboration with Multibeam, as we look for new opportunities to drive advances in lithography for our customers. With a complete set of tools in our portfolio that are used in all stages of tapeout operations, such as Proteus, CATS, SmartMRC and S-Litho, we are able to add unique value to our partners such as Multibeam and elevate the capabilities of the hardware tools that they create”, said Dr Kostas Adam, Vice President of Mask Solutions Engineering at Synopsys.